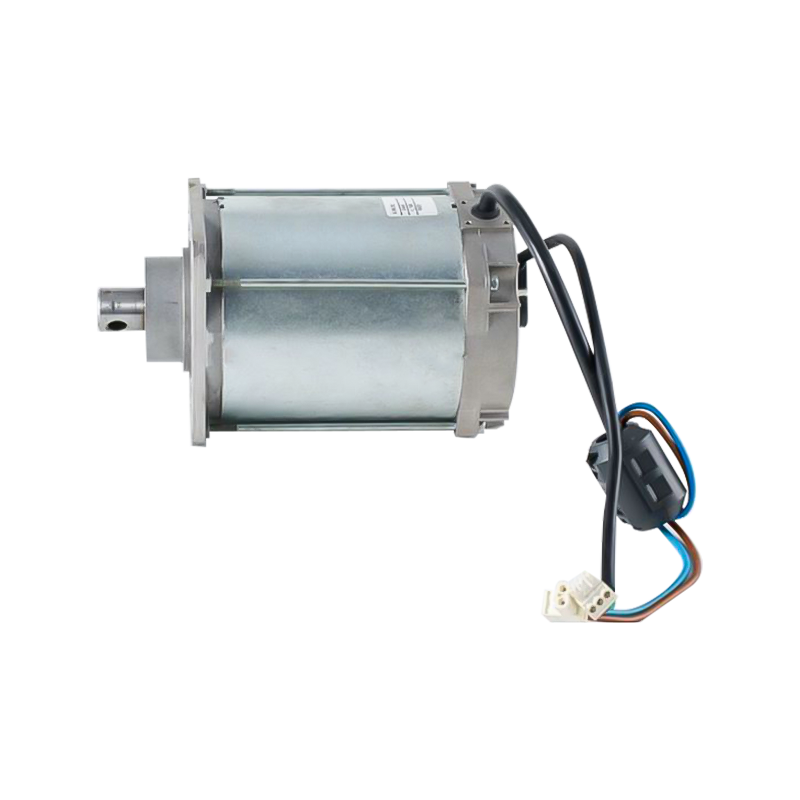

Industrial Winding Machine Motor

Description:The Industrial Winding Machine Motor is a vital component in various...

View MoreAn industrial motor is a robust, high-performance machine designed to power various types of industrial equipment and processes. Unlike standard household motors, industrial motors are engineered to handle demanding applications with higher loads, operate continuously over extended periods, and withstand harsh environmental conditions. They are integral to the functioning of machinery in sectors such as manufacturing, construction, mining, and energy production. Industrial motors come in different types and sizes, each tailored to specific operational requirements and industry standards.

1. Key Features of Industrial Motors

Durability and Robustness: Industrial motors are engineered to endure rigorous conditions. They are typically housed in rugged casings that protect them from dust, moisture, and hard temperatures. This robustness ensures that they can operate reliably in environments such as factories, mines, and outdoor settings where exposure to harsh elements is common.

High Efficiency: Efficiency is a critical factor for industrial motors. High-efficiency motors minimize energy consumption, which not only reduces operational costs but also lessens the environmental impact. Advanced technologies such as variable frequency drives (VFDs) and high-efficiency windings contribute to better performance and lower energy usage.

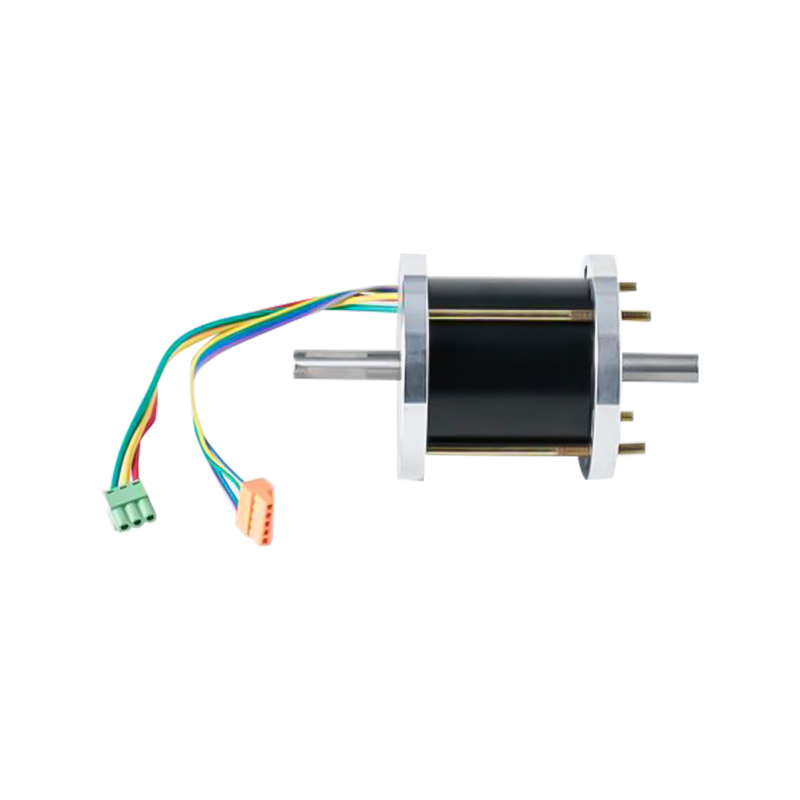

Versatility and Customization: Industrial motors come in a variety of types, including AC (Alternating Current), DC (Direct Current), and stepper motors, each suited for specific applications. They can be customized to meet the unique needs of different processes, from high-torque applications to precise motion control.

Performance and Reliability: Industrial motors are designed to deliver consistent performance and reliability. Features such as high torque-to-weight ratios, low maintenance requirements, and extended operational lifespans make them suitable for critical applications where downtime can lead to significant losses.

Safety Features: Safety is paramount in industrial settings. Motors are often equipped with built-in safety features such as thermal protection, overload protection, and fault detection systems. These features help prevent accidents, equipment damage, and ensure smooth operation.

2. Applications of Industrial Motors

Manufacturing: Industrial motors are integral to manufacturing processes, powering machinery such as conveyor systems, pumps, compressors, and mixers. Their reliability ensures smooth production lines and efficient operation.

Transportation: Motors play a vital role in transportation systems, including trains, elevators, and material handling systems. They provide the necessary power for lifting, propulsion, and movement of goods and passengers.

Energy: In the energy sector, motors are used in generators, turbines, and various other equipment. Their performance and efficiency are critical to the reliable generation and distribution of power.

Agriculture: Industrial motors are used in agricultural equipment such as tractors, harvesters, and irrigation systems. Their durability and efficiency help enhance productivity and reduce operational costs.

3. Considerations for Selection and Maintenance

Application Requirements: When selecting an industrial motor, it is important to consider the specific requirements of the application, including power needs, environmental conditions, and operational demands. Choosing the right motor ensures optimal performance and longevity.

Maintenance: Regular maintenance is essential for keeping industrial motors in good working condition. This includes inspecting and replacing components such as bearings, brushes, and cooling systems, as well as ensuring proper lubrication and cleaning.

Understanding the types, features, and applications of industrial motors helps in selecting the right motor for specific needs, ensuring reliable performance and long-term benefits.

Description:The Industrial Winding Machine Motor is a vital component in various...

View More

Description:The 230 Industrial Permanent Magnet Electric Motor is a cutting-edge...

View More

Description:The 231 high-power DC Electric Motor is engineered to meet the rigor...

View More

Description:In the ever-evolving field of medical technology, reliable and effic...

View More

Description:The 2236 High-Speed DC Motor is a cutting-edge solution designed spe...

View More

Description:The 4271 Industrial Large Torque Mini Adjustable Speed Motor is engi...

View More

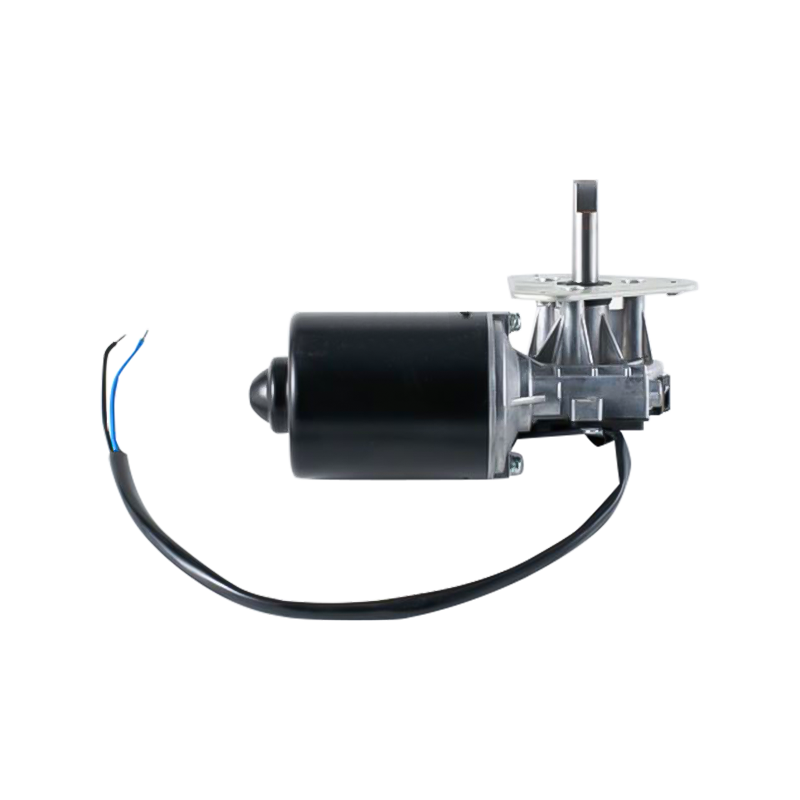

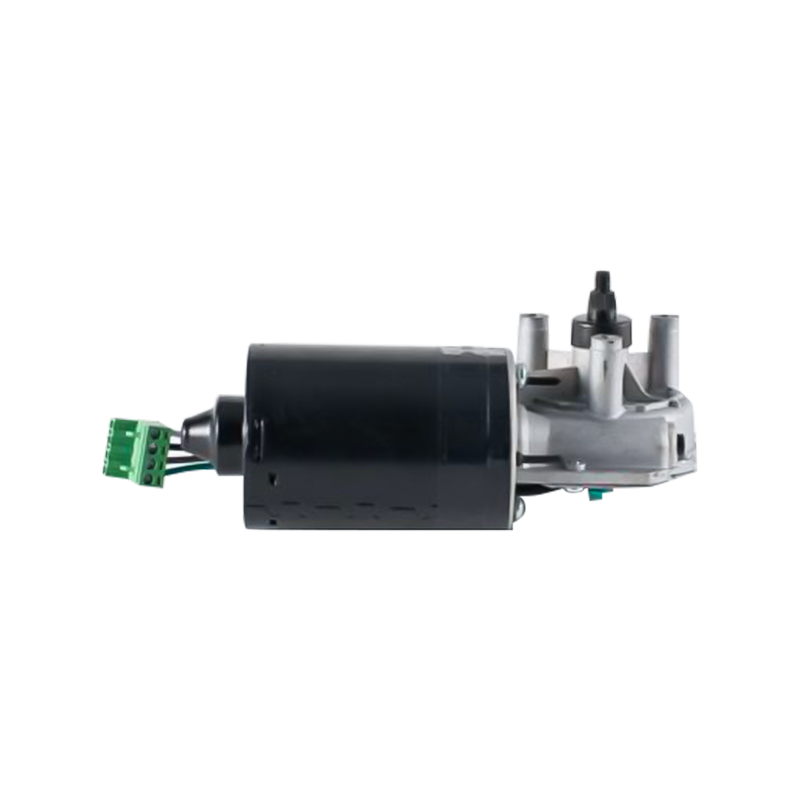

Description:The 5039 Industrial Worm Small Brush Gear Motor is a versatile and e...

View More

Overview:Worm gear motor with anti-interference device, fiberglass gear, large o...

View More

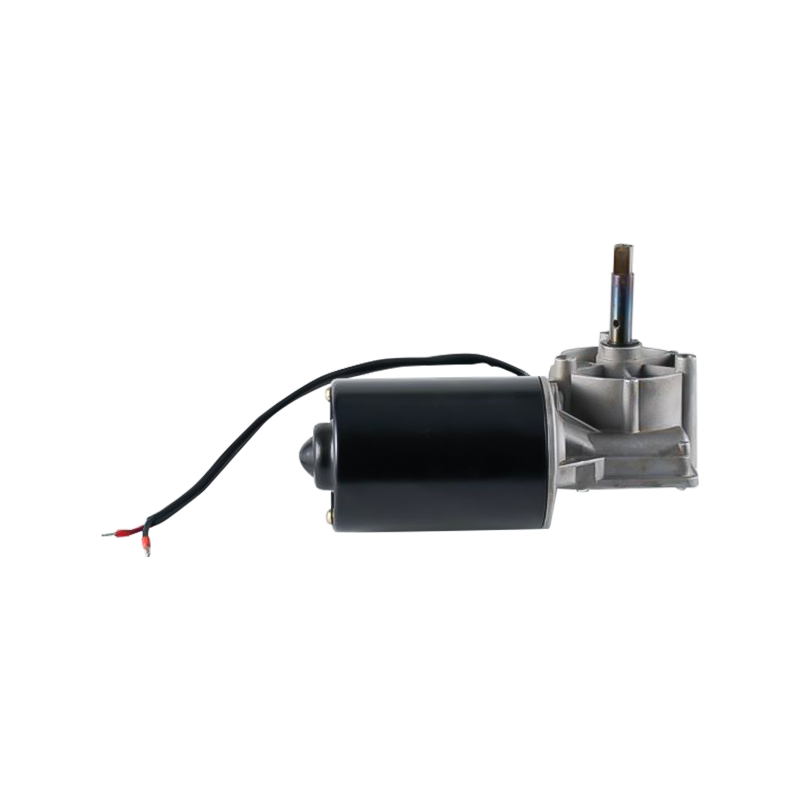

Description:The NC-1012 Big Power Roller Garage Door Motor with Gear Box is an a...

View More

Description:The NC-1022 Multipurpose Gearbox Brush Medical Motor is a state-of-t...

View More

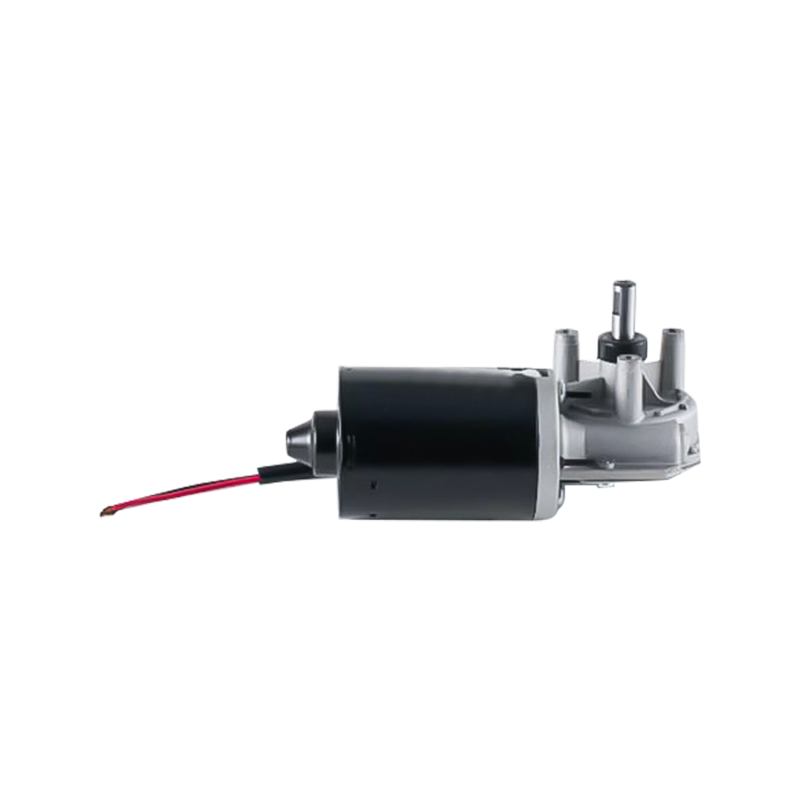

Description:The NC-2234 is a robust and efficient 12/24V DC brush motor specific...

View More

Description:The NC-2235 Industrial Electric DC Motor is a high-performance motor...

View More

Overview:Worm gear reduction motor with resistance, large output torque, high tr...

View MoreNC Motor Co., Ltd. is a professional China wholesale Industrial Motor manufacturer and sale Industrial Motor factory that integrates research and development, design, manufacturing, sales, and service. Our products include: Automatic door motors, Pump motors, Wiper motors, industrial equipment motors, etc., widely used in automatic door systems, medical equipment, the automotive industry, and other fields. Our company has established a perfect quality assurance system, combined with advanced quality control equipment, relying on leading motor control technology and strict testing means, to ensure that the quality of our products is stable and reliable.

The company has passed ISO9001:2008 and TS 16949 international quality system certification, we have been making unremitting efforts to DC brush and brushless motor research and development, science and technology as the guide, timely introduction of advanced science and technology at home and abroad, update equipment, and constantly improve the level of enterprise management and production. Products have been exported to Europe, North America, the Middle East, Southeast Asia, and other regions, with excellent quality and praised by domestic and foreign customers.

The company adheres to the principle of high, new, and special development, pursues the enterprise spirit of "survival by quality, development by-products", adheres to the enterprise philosophy of "unity, excellence, endeavor, integrity, pragmatism, and innovation", and takes "far beyond the industry pioneer, Xiang proud industry hegemon" as the enterprise purpose, and strives to provide first-class products and services for the revitalization and development of China's motor industry.

Importance of Protection Mechanisms in DC Motors In modern industrial applications, protection mechanisms play...

Introduction to Motor Starting Methods Selecting the appropriate starting method is a critical decision for an...

Basic Concept and Construction Understanding the difference between a DC Brush Motor and a brushless DC motor ...

Understanding High-Temperature and High-Pressure Challenges Operating a Steam Pump Motor in a high-temperature...