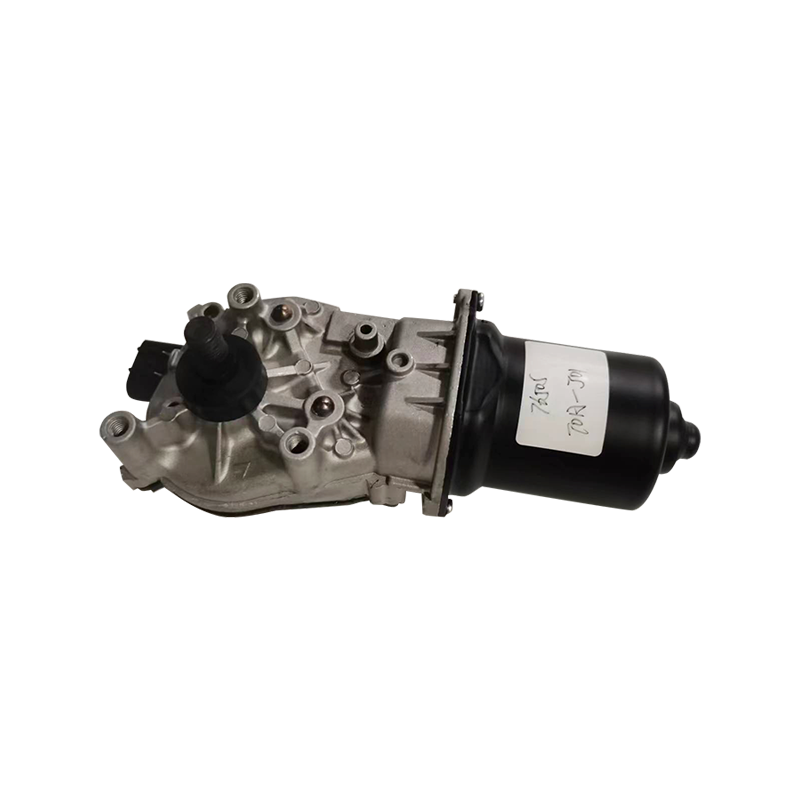

BT001 Honda Accord Windshield Wiper Motor

Power Voltage 12V DC, 35W No-load Current Low speed ≦1.5A, high speed ≦2.0A No-loa...

View MoreThe performance of a DC Brush Motor is closely tied to its load capacity and startup characteristics. These factors determine how efficiently the motor converts electrical energy into mechanical motion, how quickly it responds to changes, and how reliably it operates under varying conditions. Understanding the influence of load and startup behavior is crucial for engineers and designers seeking to optimize system performance in applications ranging from industrial machinery to consumer electronics.

Rated Load vs. Overload: Every DC Brush Motor has a rated load, which is the continuous mechanical load it can handle without overheating or suffering wear. Operating consistently above this rating can cause accelerated brush and commutator wear, increased vibration, and reduced efficiency.

Torque Requirements: The load directly affects the torque demand on the motor. A higher load requires higher torque, which may result in increased current draw. Excessive current can cause overheating and potential damage to the motor windings.

Energy Efficiency: Operating near the rated load ensures the motor runs efficiently. Underloading the motor may also reduce efficiency, as motors are typically designed for suitable performance within a specific load range.

Inrush Current: When a DC Brush Motor starts, it can draw several times its rated current, known as inrush current. This spike can stress power supplies, fuses, and control circuits if not properly accounted for.

Acceleration and Ramp-Up Time: The time it takes for the motor to reach its operating speed depends on its startup characteristics and the connected load. A motor with slow acceleration may not respond adequately in applications requiring rapid speed changes.

Impact on System Stability: Uncontrolled or abrupt starts can cause mechanical stress on connected gears, belts, or other driven components, potentially reducing system reliability. Smooth startup procedures and soft-start controllers help mitigate these issues.

Startup Under Full Load: Starting a DC Brush Motor while under heavy load increases both torque and current demands. If the motor is undersized for the load, it may fail to reach operating speed or cause tripping of protection devices.

Thermal Considerations: Repeated startup cycles under high load can generate excessive heat, causing insulation breakdown and reduced motor lifespan. Proper thermal management and adequate cooling are essential.

Voltage Drop Effects: High startup current can cause significant voltage drops in the supply system, affecting other components and causing unstable operation. Designing the system to accommodate these fluctuations is critical.

Load Matching: Selecting a motor whose load capacity closely matches the expected operating load ensures high efficiency, longevity, and reliable operation.

Startup Control: Using soft-start circuits or electronic controllers can limit inrush current and reduce mechanical stress, enhancing overall system stability.

Regular Monitoring: Continuous monitoring of current, temperature, and load ensures that the DC Brush Motor operates within safe limits, preventing unexpected failures and downtime.

The load capacity and startup characteristics of a DC Brush Motor have a profound impact on system performance. Properly matching the motor to the expected load ensures efficient torque delivery, optimal energy consumption, and long operational life. Startup behavior, including inrush current and acceleration rate, influences both electrical and mechanical system stability. By carefully considering these factors and implementing appropriate controls, engineers can optimize motor performance, protect connected components, and achieve reliable, efficient system operation.