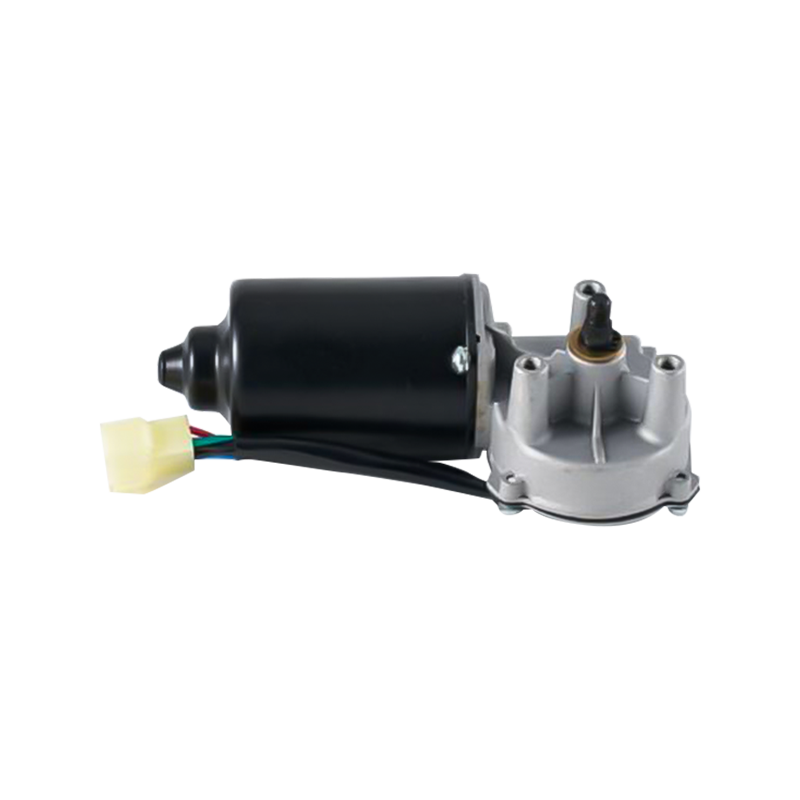

BT001 Honda Accord Windshield Wiper Motor

Power Voltage 12V DC, 35W No-load Current Low speed ≦1.5A, high speed ≦2.0A No-loa...

View MoreUnderstanding the difference between a DC Brush Motor and a brushless DC motor begins with their basic construction. A traditional brushed motor uses physical brushes and a commutator to deliver current to the rotating armature. This mechanical switching process allows the motor to generate torque with a relatively simple design. In contrast, a brushless DC motor eliminates brushes and relies on electronic controllers to switch current through the stator windings. This fundamental structural difference influences performance, durability, and application suitability across various industries.

The operating principle of a DC Brush Motor is straightforward to implement. When voltage is applied, current flows through the brushes and commutator, creating a magnetic field that causes rotation. Speed control is typically achieved by adjusting the supply voltage or using basic pulse-width modulation. Brushless DC motors, however, depend on electronic commutation. Sensors or sensorless algorithms detect rotor position and precisely control the switching of current. This electronic control allows for smoother operation, higher efficiency, and more accurate speed regulation, but also increases system complexity.

Efficiency is one of the significant differences between the two motor types. Brushed motors experience energy losses due to friction between brushes and the commutator, as well as electrical arcing during operation. These losses reduce overall efficiency and generate additional heat. Brushless DC motors reduce mechanical friction and electrical losses, resulting in higher efficiency and better thermal performance. This advantage makes brushless motors more suitable for energy-sensitive applications such as electric vehicles, drones, and high-end industrial equipment.

Maintenance requirements clearly separate these motor technologies. Brushed motors require periodic inspection and replacement of brushes, as they wear down over time. The commutator may also need cleaning or resurfacing to maintain performance. These maintenance needs limit the service life and increase downtime in continuous-use applications. Brushless DC motors, with no brushes to wear out, offer significantly longer operational life and reduced maintenance demands. This reliability is especially valuable in applications where access for servicing is limited or costly.

Noise and vibration characteristics differ noticeably between the two motor types. Brushed motors tend to produce more electrical noise and mechanical vibration due to brush contact and sparking. This can interfere with sensitive electronic systems and reduce user comfort in consumer products. Brushless DC motors operate more quietly and smoothly because of their contactless design. Improved reliability and lower electromagnetic interference make brushless motors preferable in precision equipment and noise-sensitive environments.

Cost remains an important factor when comparing brushed and brushless motors. Brushed motors are generally less expensive upfront due to their simpler construction and minimal control requirements. This makes them attractive for low-cost devices, short-duty applications, or systems where sophisticated control is unnecessary. Brushless DC motors require dedicated electronic controllers, increasing initial cost and design complexity. However, their higher efficiency, longer lifespan, and lower maintenance often result in reduced total cost of ownership over time.

The primary differences between brushed and brushless DC motors lie in their construction, efficiency, maintenance needs, and control complexity. A DC Brush Motor offers simplicity and low initial cost, making it suitable for basic or intermittent applications. Brushless DC motors excel in efficiency, longevity, and performance, making them ideal for modern, high-demand systems. Choosing between these two technologies depends on application requirements, budget considerations, and long-term operational goals.