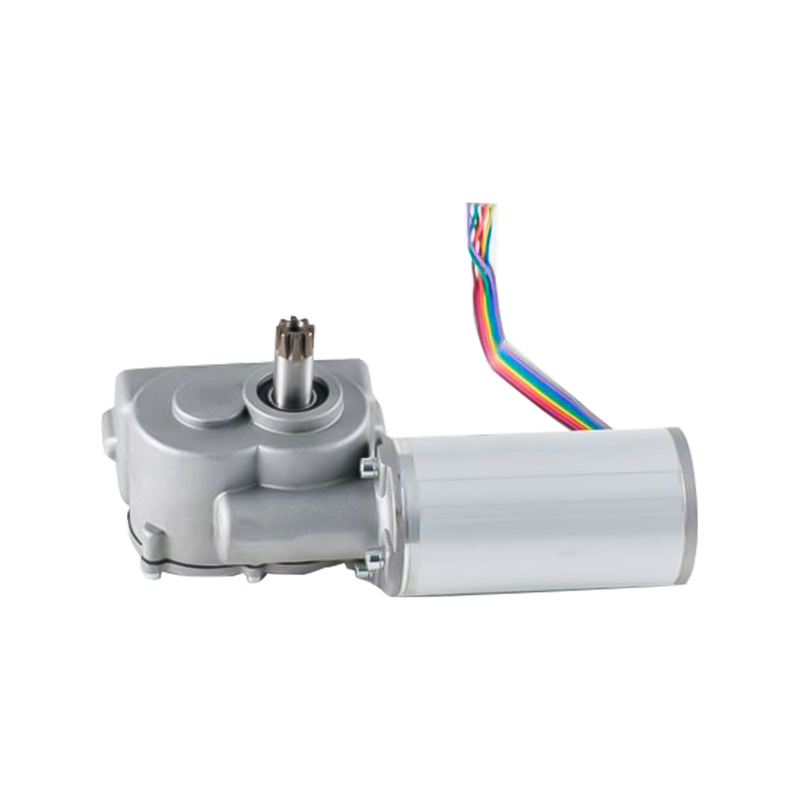

BT001 Honda Accord Windshield Wiper Motor

Power Voltage 12V DC, 35W No-load Current Low speed ≦1.5A, high speed ≦2.0A No-loa...

View MoreEnergy Use in Automatic Door Motors

Automatic doors have become a common feature in modern buildings, providing convenience and accessibility. At the heart of these systems is the Automatic Door Motor, responsible for powering the opening and closing of doors. While these systems offer significant benefits, one common concern among building owners and managers is energy consumption. Understanding how much energy these motors use and how to optimize their efficiency is crucial for reducing operational costs and the environmental impact of the building.

Factors Affecting the Energy Consumption

The energy consumption of an Automatic Door Motor depends on several factors. The type of door system (sliding, swinging, folding, etc.), the motor’s power rating, and the frequency of use all play a role. In general, motors that operate heavier doors or those with more complex mechanisms tend to consume more energy. Additionally, systems that are in constant use, such as those in high-traffic areas, will naturally consume more electricity than those in quieter, less-frequented spaces.

The efficiency of the motor itself also contributes to overall energy consumption. High-quality motors designed with energy efficiency in mind tend to use less power for the same performance compared to older or lower-grade models. Over time, advancements in motor technology have led to the development of more energy-efficient motors that reduce power usage without compromising performance.

Operational Conditions and Their Impact on Energy Usage

Energy consumption also varies depending on the operational conditions of the Automatic Door Motor. For example, motors that operate in harsh environmental conditions, such as extreme temperatures or high humidity, may require more energy to maintain consistent performance. Cold weather, for example, can make motors less efficient, causing them to use additional power to overcome increased friction or to keep the system functioning in lower temperatures.

In addition, poorly adjusted doors or motors that are not properly maintained can consume more energy. For example, if the door is out of alignment, it may struggle to open or close, requiring the motor to exert more power than necessary. Regular maintenance, such as lubricating moving parts and ensuring proper door alignment, can help reduce unnecessary energy consumption and extend the life of the motor.

Energy-Saving Features in Modern Automatic Door Motors

Today’s Automatic Door Motors are designed with energy-saving features that make them more efficient than ever. Many models include standby modes, which allow the motor to reduce its power usage when the door is not in use. These motors are often equipped with sensors that detect when the door is idle and automatically switch to a low-power mode, conserving energy during periods of inactivity.

Another energy-saving feature is the use of soft-start/soft-stop technology, which gradually accelerates or decelerates the door instead of using sudden bursts of power. This not only reduces the motor’s power draw but also reduces wear and tear, increasing the motor's lifespan.

Some Automatic Door Motors also have adjustable speed settings. By lowering the speed of the door during non-peak hours or in areas with less traffic, these systems can significantly reduce energy usage. For example, a slower-opening door consumes less power than one that opens quickly, which can be especially useful in commercial spaces or office buildings.

Tips for Optimizing the Energy Efficiency of Automatic Door Motors

While energy-efficient Automatic Door Motors are a great start, there are several ways to further optimize energy use. Regularly maintaining the system, such as cleaning sensors and checking the motor’s alignment, ensures that the system operates efficiently. Additionally, ensuring that the door is properly sealed can prevent drafts and reduce the load on the motor.

Installing motion sensors that only activate the door when needed can also help conserve energy. This is particularly useful in low-traffic areas, where the door may otherwise remain open unnecessarily. In high-traffic areas, setting the motor to operate at a slower speed or utilizing low-power modes during off-peak hours can cause noticeable savings.